Seal Test / Sealing Test trading|seal strength testing for packaging : member club Seal strength testing involves preparing samples, controlling test conditions (e.g., peel speed, load application), and interpreting results based on acceptance criteria. Protocols .

web5 de jan. de 2024 · Daher habe ich für euch die besten Casinos ohne 1 Euro Limit mit staatlichen Glücksspiellizenzen in Europa getestet. Ich erkläre euch außerdem kurz .

{plog:ftitle_list}

Em Portugal, existem algumas casas de apostas ativas que permitem apostar em .

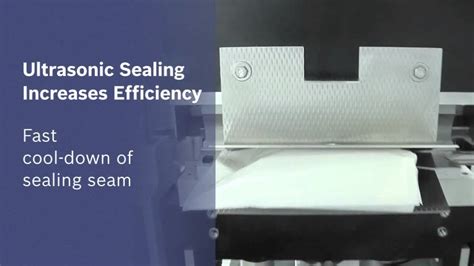

ultrasonic seal testing

Testing the integrity of package seals helps ensure that food packaging provides required product protection. Sustainable packaging alternatives, lower cost packaging, and variations in production line sealing parameters are frequently .November 10, 2021. 3 Min Read. Enhanced package seal integrity is once again top-of-mind due to recent supply and demand challenges that include these six reasons: Obtaining consistent seal layers; Fine-tuning package layers to .Analyze seal strength data using statistical methods to identify trends and outliers. Calculate average seal strength, standard deviation, and coefficient of variation. Use N-gram analysis to .This Greener Tech Bite explains the objectives, methods, results, and limitations of seven common seal tests for packages produced by flow wrappers and vertical baggers. We begin .

ASTM F88 is a test method in which packaging engineers can define seal strength requirements, like a minimum seal strength. We define what minimum seal strength is by conducting a DOE to find out what is the best . Seal strength testing involves preparing samples, controlling test conditions (e.g., peel speed, load application), and interpreting results based on acceptance criteria. Protocols .By prioritizing seal integrity testing, you’re taking a crucial step toward upholding excellence in your food packaging processes. FlexPak Leak Detectors provide the reliable, industry-leading testing solutions you need to maintain the .

Explore the seal integrity test, its importance in packaging, and how Jacob White Packaging ensures product safety and quality through rigorous testing procedures.Seal strength testing evaluates the mechanical strength of the seal, assuring proper bonding and providing an indicator of package integrity throughout the life of the package for a variety of pouch package systems holding drug product or . This chapter reviews the full range of seal testing techniques used in packaging operations to check for seal faults. The faults that are the subject of the tests can be grouped .If your house qualifies, you might be able to get a complete home air sealing package (including duct sealing and insulation upgrades) for ZERO money upfront. Get whole-house air and duct sealing—for NO upfront cost. Yes, .

To achieve vacuum level sealing, a maximum surface roughness of 16 μin. (0.41μm) has been recommended.3 Therefore, sealing surfaces on the test fixtures had to have surface finishes of 16 μin. or better. The sealing surfaces on both sides of the interface also had to be precisely aligned so that the amount of compression on the seal testVarious criteria such as the force required and the chamfering of the sealed seam are evaluated. Alongside the seal check, the ink test and the seal seam strength test, the peel test is a common method for assessing the seal seam quality of a sealing device. Performing the peel test makes it possible to detect and rectify faulty seals in good time.The test procedure may be used to test seals of alternate size and design or using alternative media but such deviations shall be detailed separately on the report form and the results shall not be used to determine the minimum operating temperature of seals .

Product Description. Pouch Seal Integrity Test : Designed to test the integrity of seals on either paper/poly or Tyvek® /poly packaging material, the Pouch Seal Integrity Test checks for an intact seal, punctures, tears and open seals of heat seal and self-seal pouches. The Pouch Seal Integrity Test is packed in an aluminum package to protect the ink against .3.1.9 hot tack, n—strength of a hot seal measured at a specified time interval after completion of the sealing cycle but prior to the temperature of the seal reaching ambient. 3.1.10 hot-tack curve, n—a plot of hot-tack strength versus sealing temperature (see Fig. 3). FIG. 1 Test Strip Failure Modes F 1921 – 98 (2004) 2

During those years, he has had the opportunity to manage and/or play a key role in seal and bearing testing, test method development, final validation, defining root case analysis of failure modes and developing training materials. . Mr. Sitko has been with Trelleborg Sealing Solutions in a variety of engineering positions for the last 13 .

Manufacturer/Factory & Trading Company; ISO 9001, ISO 14001, GMP, ISO 13485 . Favorites. Car Oil Fuel Filter Sealing Test Seal Leakage Tester. US$ 699 / Set. 1 Set (MOQ) Xuzhou Sun Hong International Trade Co., Ltd. Xuzhou Sun Hong International Trade Co., Ltd. . Discover the perfect Test Machine addition with our Seal Tester.Test machines .

package inflation seal strength test. In the Creep Test, a whole package is inflated to a constant pressure, which is then held for a specified time, resulting in a pass/fail result (see Figure 5). Early users of the method for peelable seals used the test as an analogy for the pressure difference on the seals seen in the ETO

Sealing technology plays a crucial role in many industrial and consumer products. Seals serve the purpose of preventing leaks and ensuring the safety and efficiency of products, whether it be in the healthcare industry, food industry, or other industries. . It’s like putting a seal through a fitness test to make sure it’s ready for the . What is good seal strength from a sealing process standpoint? Seal strength needs to be thought of in a multifaceted way. The process of determining what makes a good seal is the ‘Make’ pillar in ISO 11607. For the ‘Ship’ and ‘Store’ pillars you must think of what good enough seal strength is to maintain the integrity of the sterile . Two of the most critical components of your Instant Pot are the sealing ring and float valve.. The sealing ring’s mission, should it choose to accept (and it always does), is creating an air-tight seal around the lid. This means all that precious steam stays inside where it belongs – helping cook your meal faster than traditional methods would allow.6. Seal test fixture capabilities Bench testing of rotary shaft seals Figure 2 shows the standard horizontal shaft test fixtures that are used to perform much of our instrumented rotary seal testing. These bench test fixtures are capable of testing seals up to 5” (127 mm) in diameter against various environments.

Dedicated TestBed (DTB) for detecting the sealing performance of Metal Rubber (MR) was designed and manufactured based on Siemens S7-200 PLC. The experiments, such as high temperature and large temperature difference experiment, could be conducted with real-time monitoring by DTB. The general design including mechanical and control part of DTB is .

seal strength testing for packaging

To test the integrity of mechanical seals fitted with a secondary containment seal. This document is general in nature and does not refer to site specific requirements. The site has the responsibility for ensuring that tests are carried out.It’s important to note that test rigs can accommodate single product testing and complete seal package testing. After all, sealing a hydraulic cylinder is a team effort, requiring all individual parts to interact as expected in unison. Sealing packages need to be carefully selected with the application and customer’s expectation in mind.

3.1.11.1 DiscussionÐ The desired outcome of the test is to peel apart the seal formed by the test instrument. Other types of ®lm failure in the tensile phase of the instrument test cycle may not represent hot tack strength. 3.1.12 hot-tack curve, nÐ a plot of measured hot-tack strength versus sealing temperature at ®xed dwell time andMaterials Lot 2 with all seals passing gross leak and fine leak test mean of 4.5E-10 atm-cm3/sec air with Std Dev 0.35. The Sealing Schedule 3 shows that a sealing technique has enough margin to get near identical results even with slight differences in materials resulting from different lots from material suppliers. Instructions for Use: Pouch Seal Integrity Test Brand Name of Product Pouch Seal Integrity Test Generic Name of Product Pouch Seal Integrity Test Product Code Number(s) PS-001, TPS-001 Intended Use To test the integrity of the seals for heat seal and self-seal pouches. Range of Applications for Product Testing the sealing process for both paper/poly and .Thermal Sealing, Seal and Cut Equipment, and can be setup quickly and tested thoroughly. Excessive Die Pressure can be reduced with proper Thermal Sealing setup. TP-PAPER® will be most effective for your Heat Seal Setup and Seal Testing. Shown below is a simple Packaging Heat Seal Test application using TP-PAPER®.

Close the drain of 2 and 3 sealing chamber and then feed oil to the line between 2 and 3 seals and fill the oil to the top of the plug. Check the level of oil is not dropping; Similarly close the drain plug between 4 and 5 seals chamber and feed oil. Check for oil leakage from seal 5 in the forward area Seals should be tested through proper testing methods and standards and then appropriate seals should be selected. This study reviews the dynamic seal test methods for high-pressure liquid .The Sepha PakScan is a non-destructive test method. The machine performs a dry seal integrity test enabling manufactures to recover packs that have passed the leak test and return them to the production line. The system can identify gross holes, leaks and weak seals down to 10μm* in up to 10 packs simultaneously within 30 seconds.

Residual Seal Force - RSF RSF is the strain a compressed elastomeric rubber stopper flange continues to exert on the vial sealing surface after the crimping of an aluminum seal RSF is an easy-to-use quantitative method to standardize seal quality regardless of the capping equipment used for crimpingIt also allows us to test to the point of seal failure as well. This exact level is going to vary from package to package. Some companies take pressure testing a step further. A large food packager has an altimeter attached to their vacuum chamber. To pass the test, packages need to maintain their seal up to 36,000 feet on the altimeter. EMI/ RFI seals, waveguide seals, spring energized seals, rotary shaft seals, metal gaskets of different shapes. At INFINITIA Industrial Consulting we are experts in materials, innovation and design. If you want to perform a leak test on your materials or develop a new product, contact our prototyping team to offer you the best solution.

TEST METHOD STANDARD METHOD 112, SEAL AMSC N/A FSC 59GP. MIL-STD-202-112 FOREWORD 1. This standard is approved for use by all Departments and Agencies of the Department of Defense. 2. This entire standard has been revised. This revision has resulted in many changes to the format, but the most . detect leaks due to the use of inferior sealing .

Grain Moisture Meter (LDS-1G) service

Bem vindos! Esse canal é dedicado às coisas boas da vida. Aqui poderemos juntos se livrar de um dia ruim, através das histórias positivas que serão compartilhadas! Eu sou um simples jovem .

Seal Test / Sealing Test trading|seal strength testing for packaging